WELCOME TO YOUR SPACE.

Discover your agile, affordable, and sustainable launch solutions with Sirius

SIRIUS : A RANGE FOR

EVERY CUSTOMERS.

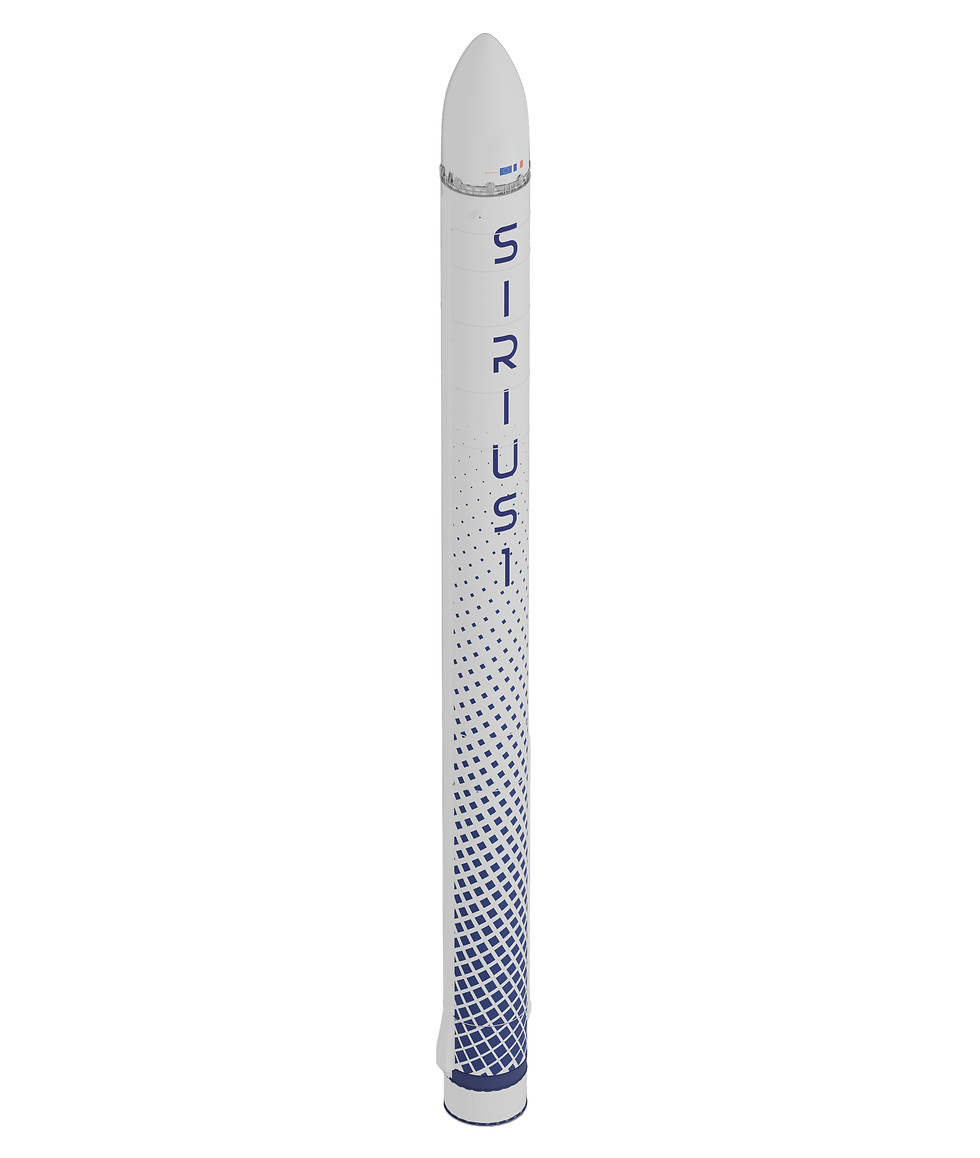

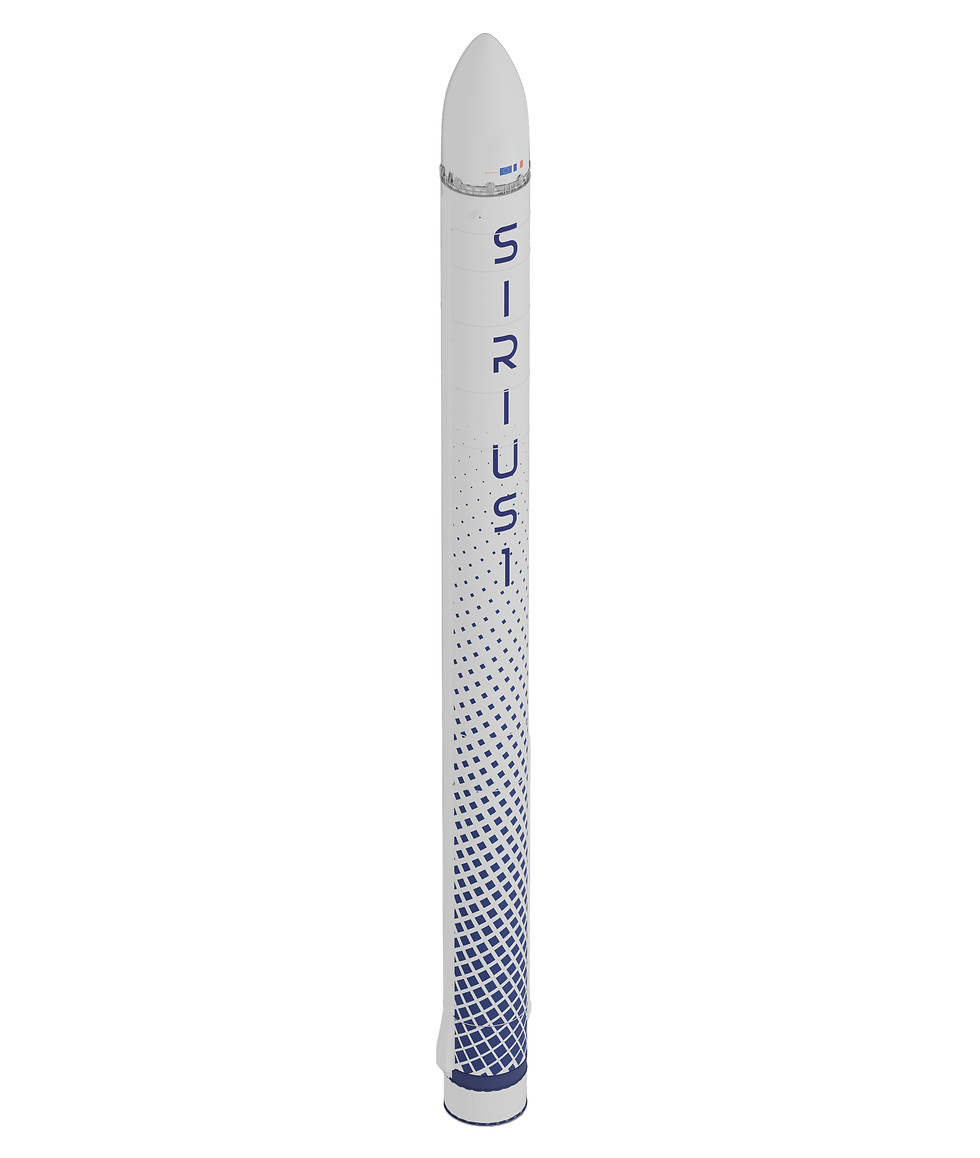

SIRIUS

Optimised for small dedicated payloads

1

SSO 500 km

300 kg at 50°

180

kg

stages

central core

tons

2

34.9

m

1

26.6

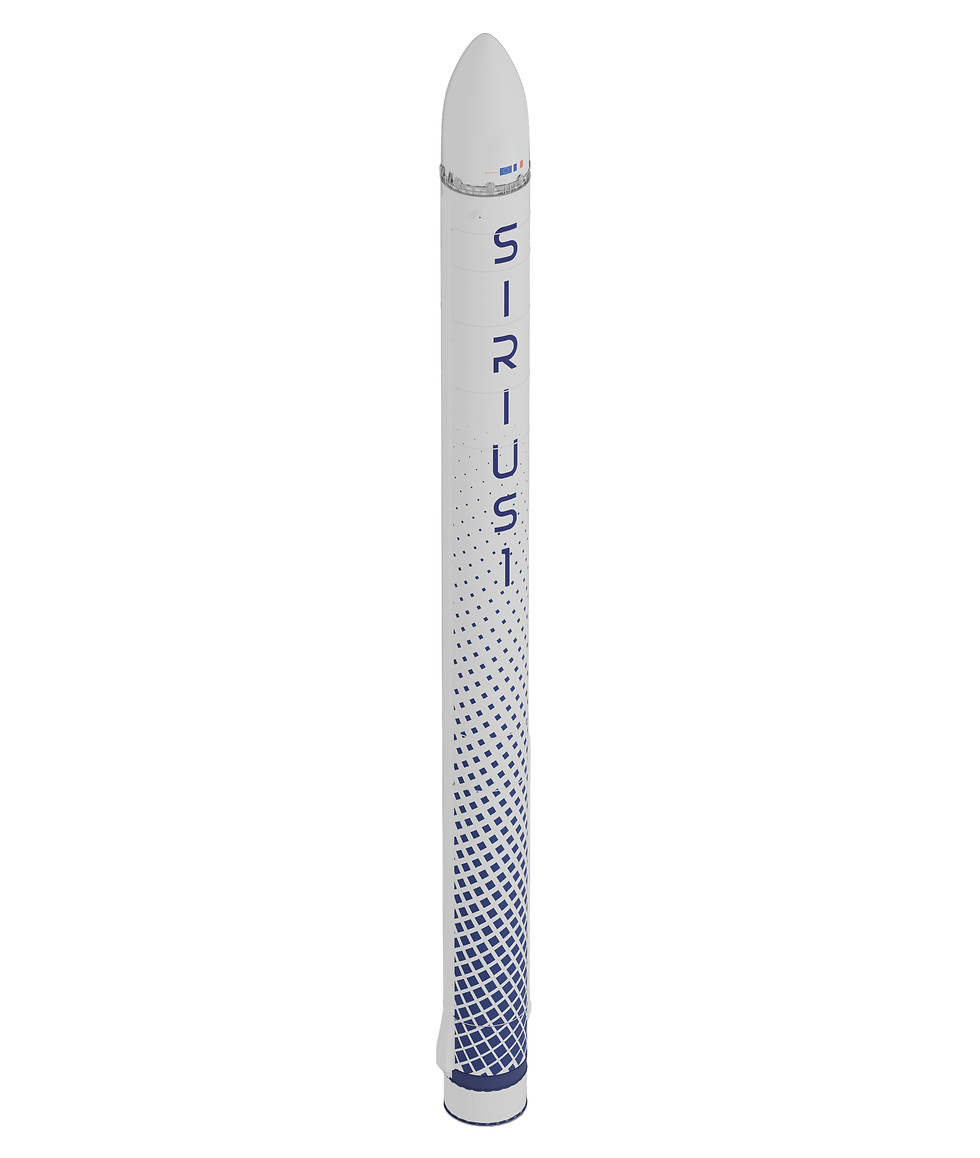

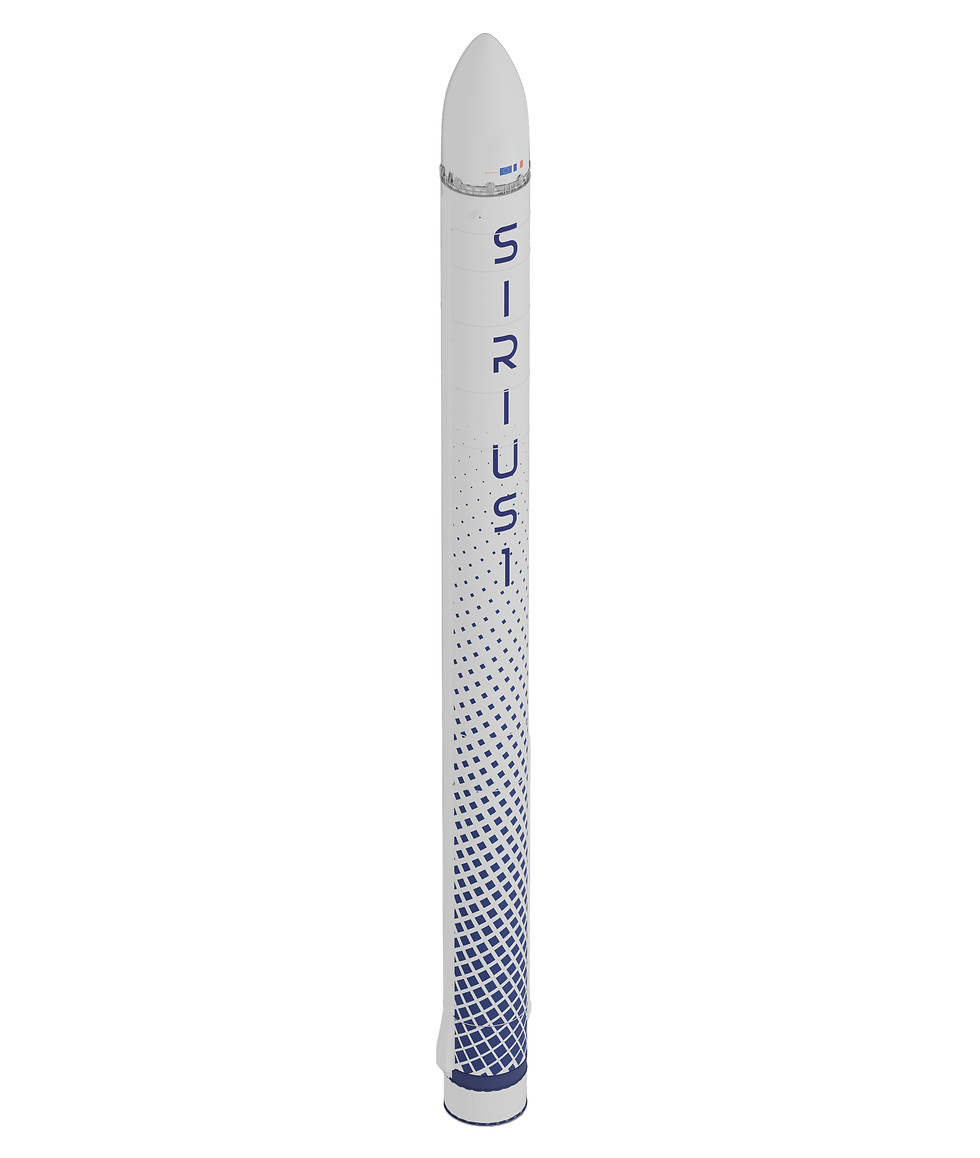

SIRIUS

Optimised for small dedicated payloads

1

SSO 500 km

300 kg at 50°

180

kg

stages

central core

tons

2

34.9

m

1

26.6

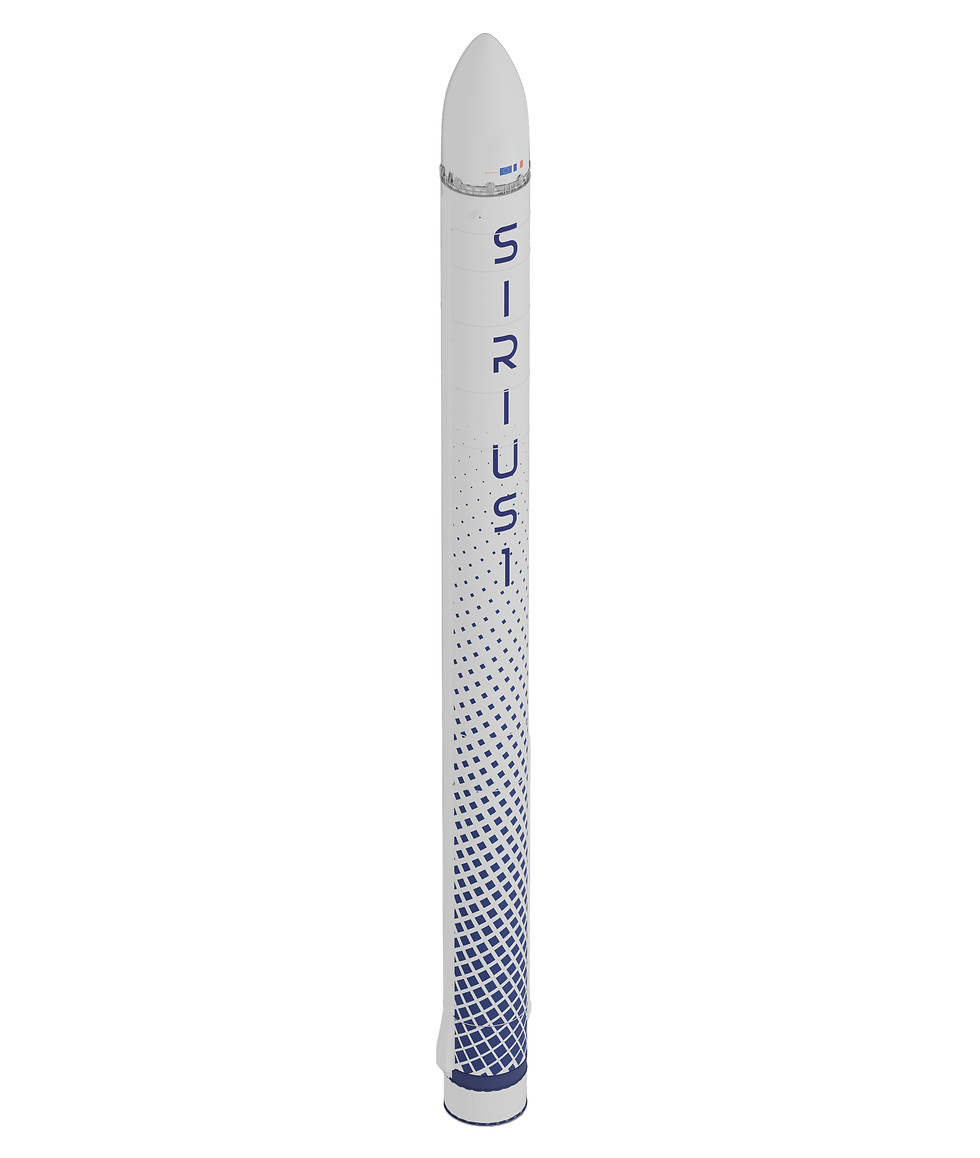

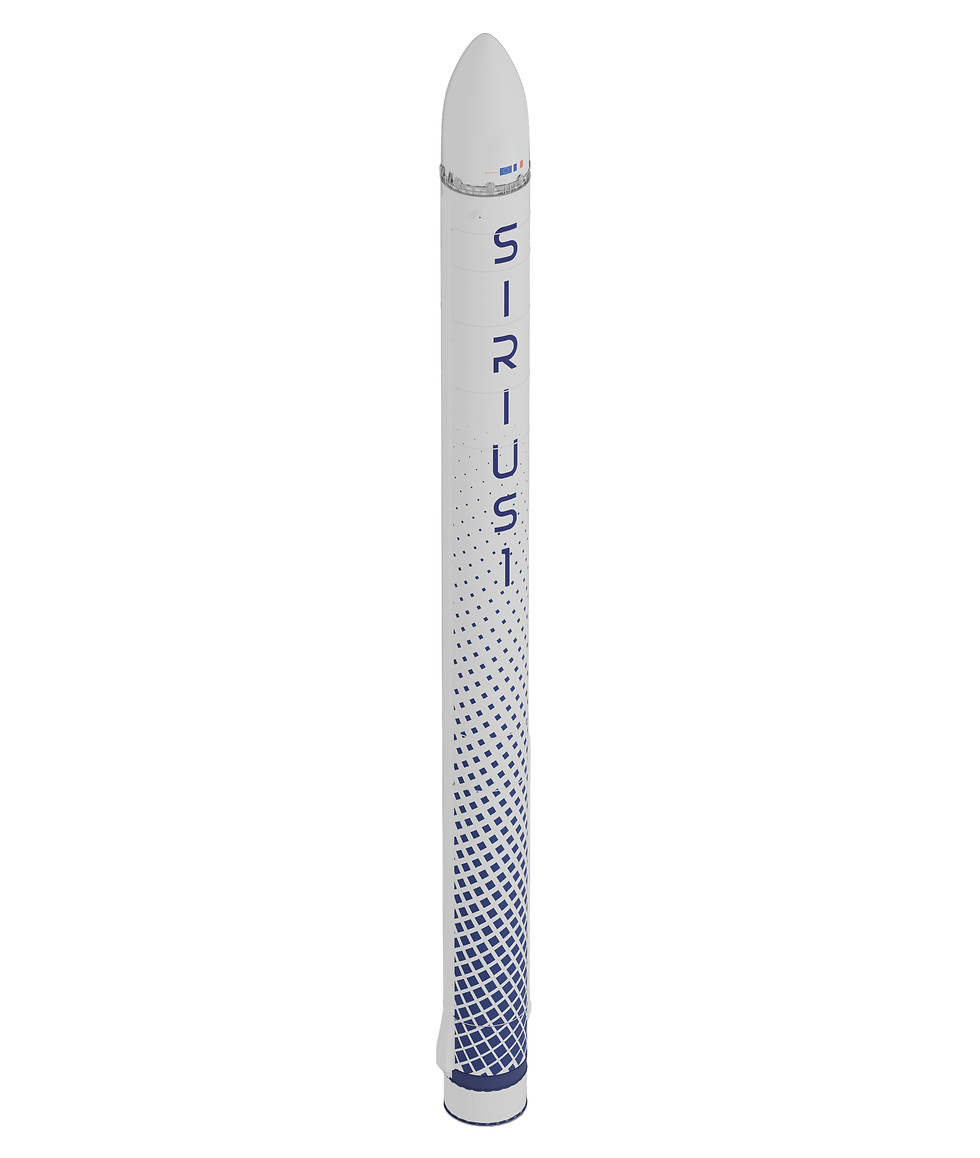

SIRIUS

1

Optimised for small dedicated payloads

180

kg

SSO 500 km

300 kg at 50°

1

central core

34.9

m

26.6

2

stages

tons

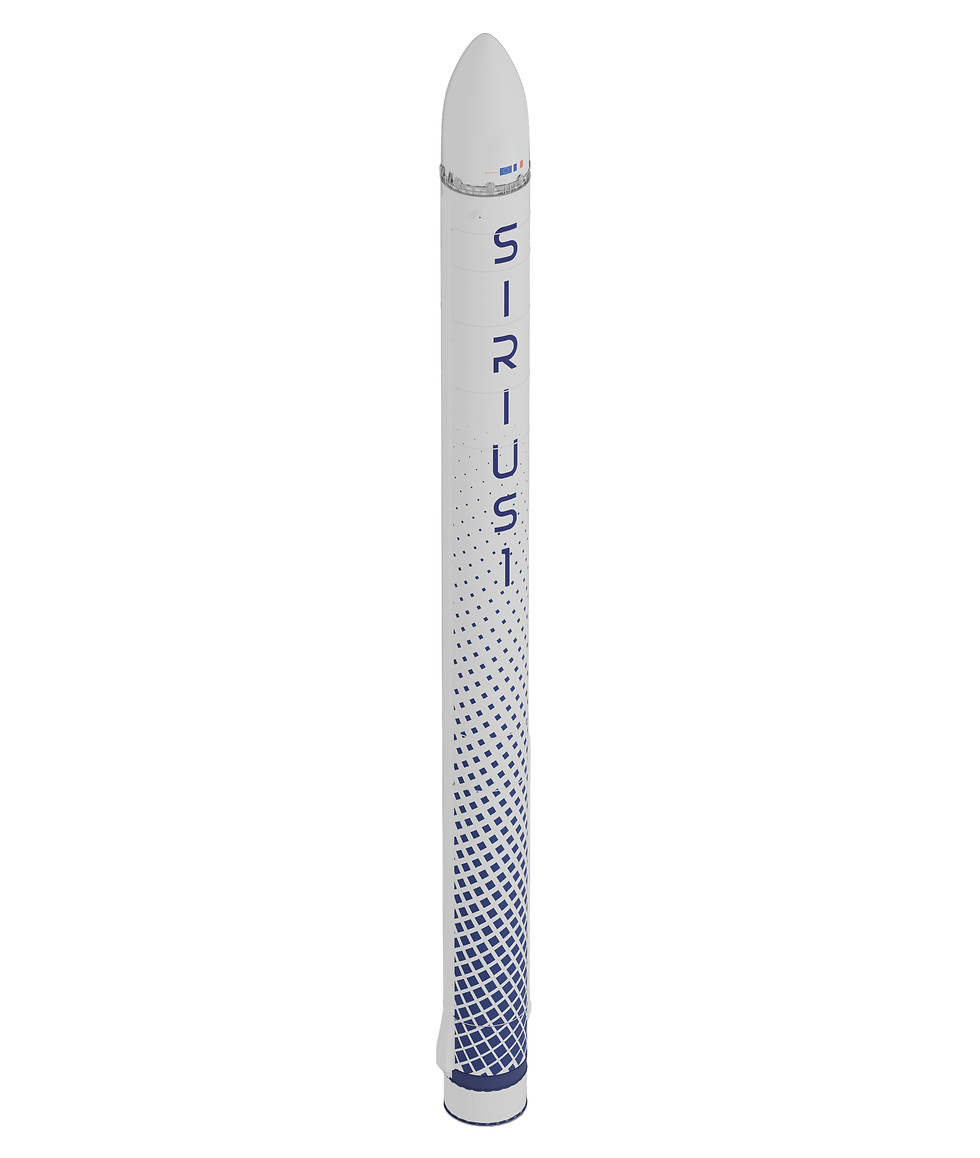

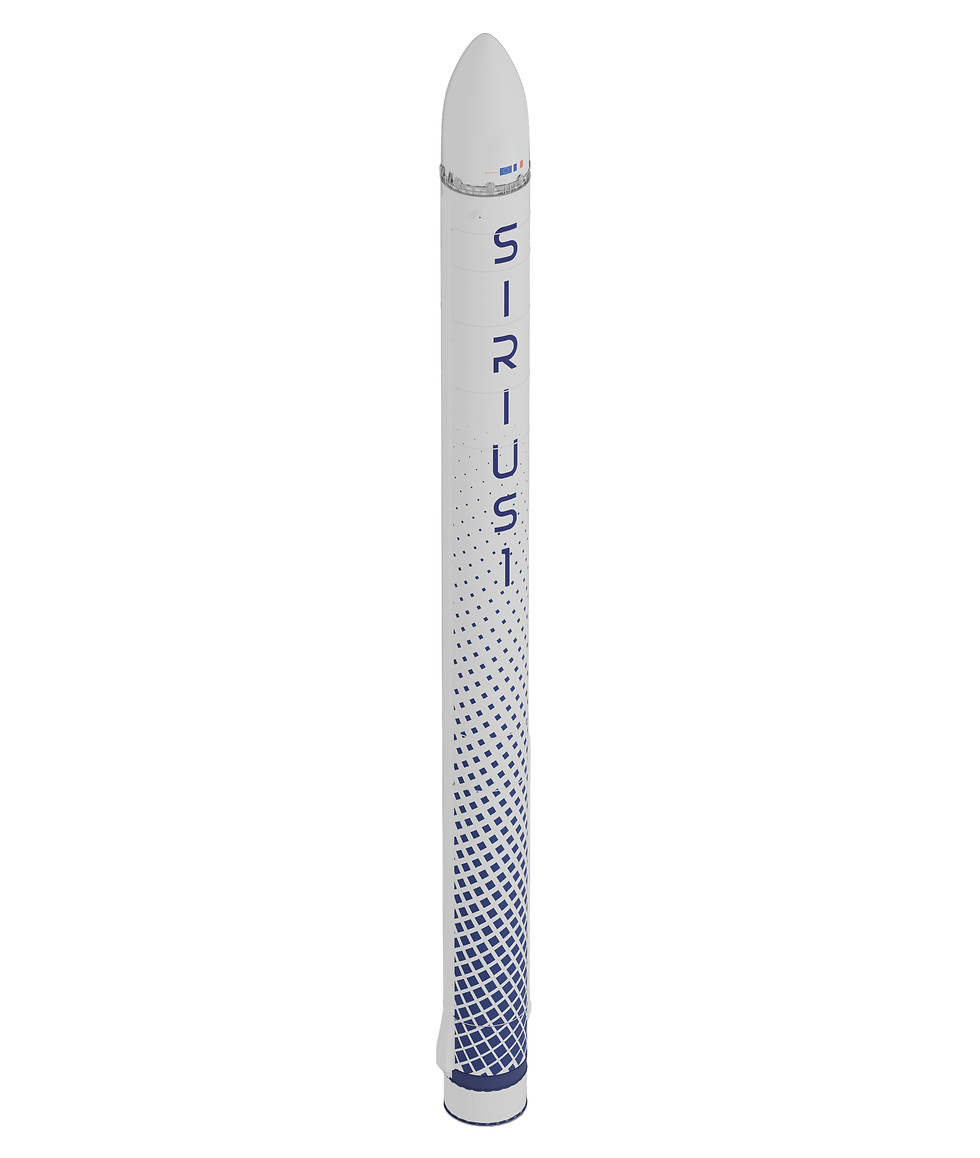

SIRIUS

Optimised for small dedicated payloads

1

SSO 500 km

300 kg at 50°

180

kg

stages

central core

tons

2

34.9

m

1

26.6

SIRIUS

13

Increased lift capacity formulti-satellite deployment

800

kg

SSO 500 km

1020 kg at 50°

1

central core

94.6

m

29.4

2

stages

tons

2

boosters

SIRIUS

Optimised for small dedicated payloads

1

SSO 500 km

300 kg at 50°

180

kg

stages

central core

tons

2

34.9

m

1

26.6

SIRIUS

15

High-capacity launchesfor heavy missions

1100

kg

SSO 500 km

1500 kg at 50°

1

central core

157.3

m

29.4

2

stages

tons

4

boosters

SIRIUS

Optimised for small dedicated payloads

1

SSO 500 km

300 kg at 50°

180

kg

stages

central core

tons

2

34.9

m

1

26.6

SIRIUS

Increased lift capacity for

multi-satellite deployment

13

SSO 500 km

1020 kg at 50°

800

kg

stages

central core

tons

2

94.6

m

1

29.4

2

boosters

SIRIUS

High-capacity launches

for heavy missions

15

SSO 500 km

1500 kg at 50°

1100

kg

stages

central core

tons

2

157.3

m

1

29.4

4

boosters

STAR-1 :

POWERING SIRIUS LAUNCHER

STAR-1

STAR-1 is produced 100% in house using Laser Powder Bed Fusion (L-PBF), a state-of-the-art 3D printing technique.

This approach boosts performance and speeds up development, helping us push the limits of spaceflight.

Each first stage will be equipped with 9 STAR-1 engines, and the second stage with a single engine. For SIRIUS 13 and SIRIUS 15, each booster will also be fitted with 9 engines.

PROPULSION

STAR-1 fueled by liquid methane and liquid oxygen, it generates a vacuum thrust of 55 kN.

STAR-1 TESTS

DECEMBER 2023

DLR-Lampolshausen - P8

60 seconds at full thrust power

OCTOBER 2024

DLR-Lampolshausen - P8

120 seconds at full thrust power

APRIL 2025

DLR-Lampolshausen - P8

140 seconds at full thrust power

STAR-1

STAR-1 is produced 100% in house using Laser Powder Bed Fusion (L-PBF), a state-of-the-art 3D printing technique.

This approach boosts performance and speeds up development, helping us push the limits of spaceflight.

Each first stage will be equipped with 9 STAR-1 engines, and the second stage with a single engine. For SIRIUS 13 and SIRIUS 15, each booster will also be fitted with 9 engines.

PROPULSION

STAR-1 fueled by liquid methane and liquid oxygen, it generates a vacuum thrust of 55 kN.

STAR-1 TESTS

DECEMBER 2023

DLR - Lampolshausen - P8

60 seconds at full thrust power

120 seconds at full thrust power

DLR - Lampolshausen - P8

OCTOBER 2024

140 seconds at full thrust power

DLR - Lampolshausen - P8

APRIL 2025